Waterproof Double Cable Entry Gland Solar RV and Marine Use

Discover durable waterproof double cable entry glands with IP68 rating ideal for RV solar panels boats and outdoor cable sealing solutions.

Read More

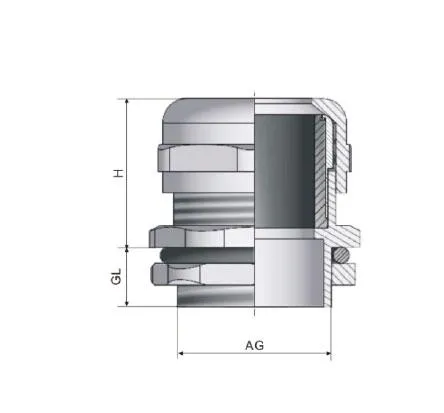

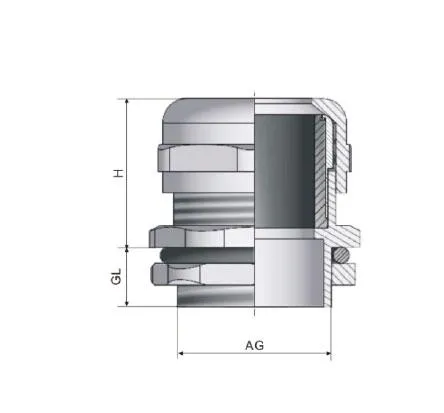

Learn how to pick the right Waterproof Cable Gland threads and sizes to protect your cables from dust and water.If you run outdoor equipment or work in harsh industrial sites, you know this already: water is your cable’s worst enemy. One tiny leak at a connection point can bring a whole system down. But don’t worry — a good Waterproof Cable Gland keeps water out and your gear running safely. If you are looking for high-quality waterproof cable gland with a wide range of specifications, feel free to contact us.

Picture this: your cable enters a junction box. There’s a hole where rain, dust, or oil could sneak in. A waterproof cable gland seals that entry point tight. It grips the cable, locks it in place, and blocks anything you don’t want getting inside.

Screw it in: The gland threads into the panel hole.

Clamp it tight: Inside, there’s a piece that squeezes the cable when you tighten it.

Seal it shut: A rubber ring forms a barrier around the cable. Done right, nothing leaks through.

| Material | Pros | Cons | Where You’ll Find It |

|---|---|---|---|

| Nylon | Lightweight, affordable, decent chemical resistance | Not ideal for high heat, may age in strong sun | Indoor boxes, basic outdoor lights |

| Brass | Strong, corrosion-resistant | Heavier than nylon, costs a bit more | Pumps, marine gear, factories |

| Stainless Steel | Tough, top corrosion resistance | More expensive | Oil rigs, food plants, high-pressure systems |

If the thread’s wrong, your seal leaks. If the hole and gland don’t match, you get loose fittings that won’t stay watertight. And if you pick odd threads, finding replacements later turns into a headache.

Here’s the bottom line:

👉Ever thought “I’ll just buy the biggest one to be safe?” Don’t. Too big, and the Waterproof Cable Gland slips right out. Too small, and you’ll damage the sheath.

In the design and application of Waterproof Cable Gland, the choice of thread type is crucial. Reasonable selection of thread type helps to improve the sealing and reliability of equipment and meet different industrial needs.

We will introduce four main thread types in detail: Metric thread has the advantages of standardization and wide applicability; NPT thread is widely used in the North American market due to its excellent self-sealing performance; PG thread is suitable for Europe and old equipment; G thread relies on sealing rings and is common in special industrial fields.

| Thread Type | Features | Typical Sizes | Applications |

|---|---|---|---|

| Metric Thread | Highly standardized, widely used globally. Strict pitch and diameter standards for easy interchange and maintenance. | M12, M16, M20, M25, M32, M40, M50, M63 | Automation equipment, instruments, cabinets |

| NPT Thread (National Pipe Thread) | American standard tapered pipe thread with 60° angle and taper. Excellent self-sealing when tightened. Mainly used in North American market and related equipment. | 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″ | Power, petrochemical, automation |

| PG Thread (Panzer-Gewinde) | German standard with larger pitch, suitable for older and some European equipment. | PG7, PG9, PG11, PG13.5, PG16, PG21, PG29, PG36 | Machinery, European market, retrofitting old equipment |

| G Thread (ISO 228) | Parallel pipe thread relying on sealing rings. Used in specific industrial fields. | 1/4″ to 3 1/2″ | Special industrial equipment, hydraulic pipelines |

Metric threads are the first choice for modern industry due to their standardization and wide application. NPT threads, with their tapered design, provide excellent sealing effects, especially suitable for the North American market. Although PG threads are an old standard, they are still irreplaceable in some European equipment. Understanding these differences can help you avoid installation problems caused by thread mismatches.

If you need multi-specification waterproof cable gland, please feel free to contact us.

When selecting thread specifications, consider cable diameter, protection rating, and actual application environment. The table below compares common thread types, sizes, and applications:

| Thread Type | Common Sizes | Applicable Cable Diameter (mm) | Protection Rating | Main Application Areas |

|---|---|---|---|---|

| Metric | M12–M100 | 3–90 | IP67/IP68 | Industrial automation, instrumentation |

| NPT | 1/4″–3 1/2″ | 8–101 | IP67/IP68 | Power equipment, North American market |

| PG | PG7–PG48 | 3–54 | IP67/IP68 | Machinery, European equipment |

| G / ISO228 | 1/4″–3 1/2″ | 8–100 | IP67/IP68 | Special applications |

Waterproof and dustproof level

Generally speaking, the outer diameter of the cable should match the specifications of the connector, and a margin of about 10% should be maintained to ensure sealing effect and installation convenience. Different IP levels represent waterproof and dustproof capabilities:

Choosing the correct protection level can ensure that the cable connector can still work reliably in harsh environments.

| Thread | Strengths | Weak Spots |

|---|---|---|

| Metric | Fits global parts, easy replacements | Needs nuts and washers |

| PG | Simple install, locks tight | Not as common outside Europe |

| NPT | Great seal with PTFE tape, fights vibration | Needs tape, not reusable without extra parts |

| G/BSP | Reusable seal with O-ring | O-ring wears out if ignored |

Besides thread type and size, pay attention to the following factors:

Device Interface Standard: Ensure the thread type matches the device interface.

Cable Diameter Matching: Measure the cable diameter accurately and select the appropriate size, leaving about 10% tolerance.

Protection Rating: Choose IP67 or IP68 based on the environment to meet waterproof and dustproof requirements.

Material Selection:

Working Environment: Consider temperature, humidity, corrosiveness, and other factors.

| Selection Factor | Description | Recommendation |

|---|---|---|

| Interface Standard | Confirm thread type | Match device requirements |

| Cable Size | Measure outer diameter | Match size with tolerance |

| Protection Rating | IP65–IP68 | Choose based on environment |

| Material | Nylon/Brass/Stainless Steel | Select according to needs |

| Environmental Conditions | Temperature/Corrosiveness | Use high-performance materials for harsh conditions |

How to Install It Right Waterproof Cable Gland, Here a quick checklist:

1️⃣ Measure First

Use calipers to check the cable’s diameter. Pick a gland that matches.

2️⃣ Prep the Hole

Clean up burrs. Check the threads and sealing ring for cracks.

3️⃣ Tighten It Up

Screw in the gland. Hand-tighten first, then use a wrench — but don’t overdo it. Insert the cable, clamp it down. You want it snug, not crushed.

| Problem | Why It Happens | Fix It |

|---|---|---|

| Gland loosens | Thread mismatch, not tight enough | Check threads, retighten |

| Water leaks in | Cracked or old seal ring | Swap the ring, check IP rating |

| Cable gets damaged | Overtightened | Loosen a bit or choose a bigger gland |

| O-ring slips | Bad fit or too much grease | Center it, reinstall |

| Model | Thread | Material | IP Rating | Where It Works |

|---|---|---|---|---|

| CN-M20-NYLON | M20 | Nylon | IP68 | Outdoor lights, junction boxes |

| CN-PG13.5-BRASS | PG13.5 | Brass | IP68 | Marine gear, chemical pumps |

| CN-NPT1/2-SS | 1/2″ NPT | Stainless Steel | IP68 | Offshore rigs, washdown stations |

Real Stories:

A solar farm used over 5,000 CN-M20-NYLON glands — no leaks in two years. A chemical plant switched to brass to resist acid. They cut downtime by 30%.

A waterproof cable gland may look small, but it saves you big headaches. Pick the right threads and size, install it right, and you won’t lose sleep over water leaks again. Contact us and we will help you find the waterproof cable connector you want quickly. We have various thread types and specifications to help you choose easily and avoid these troubles.

👉 Contact us for free samples or quick quotes.

👉 Email us now — we’ll help you find the best gland for your cables.

PG threads come from German standards. Metric is more global. Both seal well, just check what your panel needs.

Measure the cable and the hole. Use the chart.

Total dust block, plus safe for long soaks underwater.

Good ones are. Ours have UV stabilizers built in.

If the seal ring’s clean, maybe once or twice. For the best seal, swap it.