Nylon cable gland are a fundamental component for securing and sealing electrical cables as they enter enclosures. Their versatility spans industries from industrial automation to consumer electronics, delivering mechanical strain relief, environmental protection, and electrical insulation. This article dives into the concept of Nylon Cable Gland, its applications, and the electrical symbols you’ll encounter when designing or documenting electrical systems.

What is a Nylon Cable Gland?

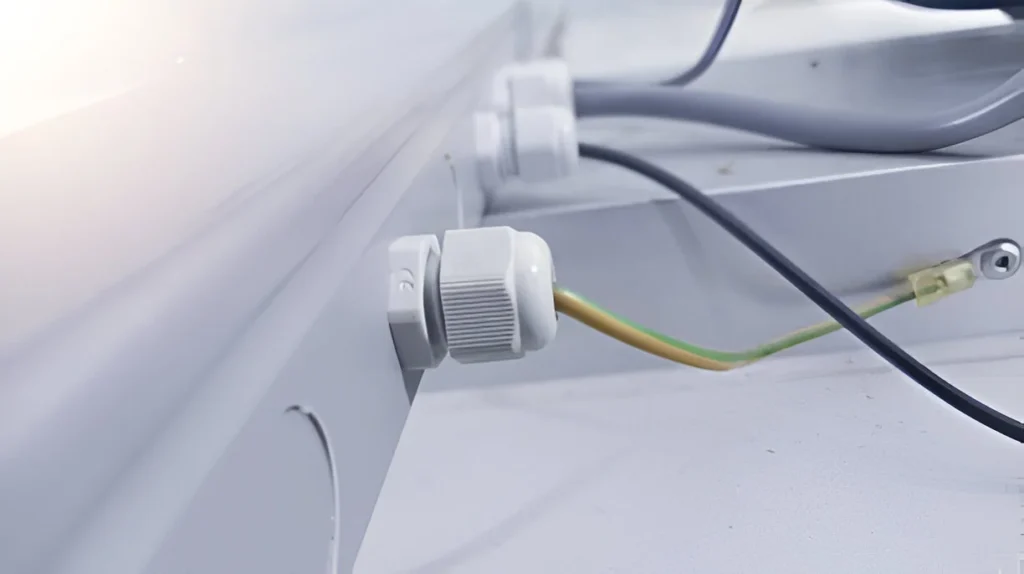

A United Structure Nylon Cable Gland nylon cable gland is a modular, cylindrical fitting made primarily from nylon (polyamide) that grips a cable and seals the entry point to an enclosure. The gland typically includes a threaded body, a sealing gasket, and a compressing nut or gland nut that locks the cable in place. The material choice—nylon—offers several benefits: lightweight yet strong construction, good chemical resistance, electrical insulation properties, and cost efficiency for bulk manufacturing.

Nylon cable glands come in various sizes, styles, and IP ratings to match different cable diameters and environmental conditions. They are widely used to protect conductors from dust, moisture, and mechanical stress while maintaining electrical safety standards.

Why Choose Nylon Over Other Materials?

Nylon offers a balanced profile for many applications. It is lighter than metal glands while maintaining adequate strength. It resists corrosion better than some plastics and provides excellent electrical insulation. It also accepts broad temperatures and is easier to manufacture in high volumes. For projects emphasizing cost efficiency without compromising protection, nylon glands are a sensible choice.

The Key Features of Nylon Cable Gland

Nylon cable glands stand out because of several practical features:

- Insulation and Protection: Nylon provides reliable electrical insulation, reducing the risk of short circuits at entry points.

- Sealing Capabilities: O-ring or gasket seals help prevent water ingress, dust, and corrosive agents, contributing to higher IP ratings.

- Strain Relief: The clamping mechanism secures the cable, reducing stress on conductors and preventing wire breakage.

- Chemical and Temperature Resistance: Nylon resists many coolants, oils, and solvents and maintains performance across typical industrial temperatures.

- Lightweight and Cost-Effective: For large-scale installations, nylon glands reduce overall weight and cost without sacrificing durability.

- Compatibility: They integrate with standard conduit fittings and enclosure systems, making them a versatile choice for retrofits and new builds.

Applications of Nylon Cable Glands

Nylon cable glands find a home in various settings:

- Industrial Automation: Machinery, control panels, and PLC cabinets require reliable ingress protection for control cables and power lines.

- Electrical Enclosures: Distribution boards, electrical cabinets, and weatherproof enclosures benefit from effective sealing at entry points.

- Outdoor and Harsh Environments: IP-rated glands shield cables against moisture, dust, and chemical exposure in outdoor installations and chemical plants.

- Marine and Automotive: Nylon glands can be selected for environments requiring resistance to salt spray and vibrations.

- Medical Equipment: Sensitive equipment relies on clean, secure cable entry seals to prevent contamination and maintain electrical integrity.

Environmental Conditions and IP Ratings

IP ratings describe how well a enclosure resists solids and liquids. For nylon cable glands, typical configurations include IP54, IP65, IP66, and IP68, depending on the gasket design and fitting tightness. In outdoor or wet environments, higher IP ratings ensure safer operation over time. The gland must be selected to match the protection level of the enclosure and the nature of the cable (inner diameter, number of cores, and conductor size). Glands also contribute to flame retardancy in certain resistor and electrical systems, an important consideration for safety compliance.

Nylon Cable Gland Electrical Symbols

When documenting electrical systems, several symbols relate to cable glands and their role:

- Cable Gland: A simple symbol showing a conduit entering an enclosure may be used to indicate the gland’s presence and function.

- Sealed Cable Entry: A symbol depicting a seal around the entry point emphasizes IP protection and weather resistance.

- Strain Relief: A symbol illustrating a clamp or gripping mechanism often indicates strain relief features.

- Grounding/Protection: In some diagrams, the gland’s metal components might be shown as connected to ground, particularly in metallic enclosures, to ensure leakage and fault paths are clear.

- IP Rating Tag: An annotation or note in the diagram may specify the gland’s IP rating to ensure appropriate environmental protection is understood by technicians.

How to Read and Use Symbols in Schematics

Documentation often uses simplified icons to convey complex protective roles. Understanding these icons helps technicians assemble, inspect, and maintain systems efficiently. When designers describe a system, they may annotate the cable entry with a note such as “Nylon gland, IP65, M20 thread” to clarify compatibility and protection. This clarity reduces misinterpretation during installation and maintenance and helps with compliance checks during audits.

Common Types of Nylon Cable Glands

Nylon cable glands come in many forms, each serving a specific need:

- Metric Nylon Glands: These glands use metric threads and are popular in European and global equipment.

- Inch Nylon Glands: Used for North American equipment or standards requiring inches-based thread sizes.

- Sealing Glands: With integrated gaskets or O-rings to maximize IP ratings.

- Weatherproof Glands: Sealings designed for outdoor or wet environments.

- Sealed Cable Glands: Additional buffering to prevent moisture ingress even under high pressure or immersion.

- Cable Gland Accessories: Locknuts, mounting plates, and sealing washers enhance installation flexibility.

Sizing and Compatibility Considerations

Choosing the right size is essential. The gland must accommodate the outer diameter of the cable and provide sufficient compression for a durable seal. A gland that’s too small may degrade insulation and cause leakage, while a gland that’s too large may not seal well or create unnecessary stress on the cable. Additionally, the enclosure’s thread type (metric or imperial) determines which gland family to select. Always verify cable diameter, number of cores, insulation thickness, and the enclosure’s IP requirement before finalizing a gland choice.

Design and Manufacturing Considerations

From a design perspective, choosing nylon for the gland balances cost, weight, and performance. Manufacturers consider:

- Material Standardization: Nylon types and grades affect strength, chemical resistance, and temperature tolerance.

- Molding and Finishing: Precision molding ensures threads, seals, and clamps perform consistently.

- Surface Treatment and Aging: Surface finishes can improve UV resistance for outdoor use.

- Compliance: Glands must meet standards such as IP ratings, UL/CSA certifications, and global electrical safety requirements.

Maintenance and Longevity Tips

Proper maintenance extends gland life:

- Regular Inspection: Check seals and gaskets for wear and replace as needed.

- Clean Entries: Remove dust and debris that can compromise seals.

- Verify Tightness: Ensure gland nuts hold cables securely without over-tightening, which can damage insulation.

- Replace Gaskets: O-rings and gaskets should be replaced when signs of aging show.

Selecting a Nylon Cable Gland for Your Project

Step 1: Determine environmental protection needs (IP rating, UV exposure, chemical resistance).

Step 2: Identify cable characteristics (outer diameter, number of cores, insulation thickness).

Step 3: Choose thread size to match enclosure (metric vs. inch).

Step 4: Decide on sealing type (gasket, O-ring, or integrated seal).

Step 5: Check compatibility with enclosure and mounting accessories.

Step 6: Verify certifications (UL/CSA/CE) and temperature ratings.

Step 7: Plan for maintenance (spares for seals and gaskets).

Comparing Nylon with Other Materials

Nylon vs. Polypropylene: Nylon offers better temperature tolerance and insulation; polypropylene may be lighter and cheaper but with less chemical resistance.

Nylon vs. Metal: Nylon provides electrical insulation and corrosion resistance but may not match the mechanical strength of metal glands; however, for most control panels and enclosures, nylon offers sufficient protection with lower weight.

Nylon vs. Thermoplastic Elastomers: Some glands use elastomeric materials for seals; nylon remains the main body with seals made from elastomer compounds for compatibility with various cables and environments.

Industries Benefiting from Nylon Cable Glands

- Manufacturing and Automation: Maintains reliability in control panels and robotic systems.

- Energy and Utilities: Protects power cables entering switchgear and meters.

- Transportation and Public Infrastructure: Ensures secure entries in signaling and lighting enclosures.

- Data Centers and IT: Seals around fiber and copper conduit entries, reducing dust ingress.

Cost and Lead Time Considerations

- Bulk purchases reduce per-unit cost; negotiate with suppliers for standard sizes and common thread types.

- Lead times vary by supplier, especially for custom configurations. Plan procurement to avoid production delays.

Nylon cable glands are a practical, cost-effective solution for securing, sealing, and protecting cables as they enter electrical enclosures. Their lightweight nature, good insulation, and robust sealing properties make them suitable for a wide range of environments—from indoor control panels to outdoor industrial installations.

By understanding the key attributes, applications, and documentation practices, engineers and procurement teams can select the right nylon gland with confidence and ensure dependable performance over the life of the system. If you’re planning a new enclosure or upgrading an existing one, consider Nylon Cable Gland as a dependable entry solution for cables and wires.

FAQ

What is Nylon Cable Gland used for?

Nylon cable glands protect and seal cables as they enter enclosures, while providing strain relief and electrical insulation.

How do you select the right size for a nylon gland?

Measure the cable outer diameter and cores, then choose a gland with a clamping range that fits snugly and provides proper sealing.

Can nylon glands be used outdoors?

Yes, with appropriate IP-rated seals. Outdoor use often requires IP65 or higher to withstand moisture, dust, and weather exposure.

Are nylon glands flame retardant?

Many nylon glands meet flame retardant specifications, but always verify the specific grade and certification for a given application.

What standards apply to nylon cable glands?

Standards vary by region but commonly include IP ratings, CE, UL, and CSA certifications. Confirm the gland meets the enclosure’s compliance requirements.