GHX stainless steel cable glands (SS304, SS316, SS316L) deliver exceptional corrosion resistance, explosion-proof performance, and waterproof ratings up to IP68/IP69K (10bar), making them ideal for use in hazardous and harsh environments.

High Waterproof & Heat Resistance: Withstand pressure up to 10bar and temperatures up to 150℃

Reliable Cable Protection: Ensures superior strain relief and structural integrity

Corrosion & Bacteria Resistance: Ideal for food, beverage, and marine industries

Wide Industrial Use: Applied in renewable energy, automation, lighting, and telecom sectors

Flexible Thread Options: Available in Metric, PG, NPT threads with short and long entries

Cost-Effective & Durable: Combines affordability with high performance and long service life

The shell is made of nickel-plated brass, the internal claws are nylon PA, and the sealing ring and O-ring are made of NBR rubber. It has flame retardant, environmental protection and safety characteristics, and the protection level is as high as IP68-10 Bar.

GHX Cable Glands feature a broad and versatile range, engineered to meet the sealing and connection needs of a wide variety of applications and industries.

Waterproof brass cable gland: Made of nickel-plated brass and NBR sealing, it offers IP68 protection, high tensile strength, and strong resistance to dust, corrosion, and water, with Metric, PG, G(PF), and NPT threads, ideal for harsh environments from -40℃ to 100℃ (up to 120℃ briefly).

Brass gland for harsh environments: Nickel-plated brass with NBR sealing provides IP68 protection, high strength, and resistance to water, dust, salt, acids, alkalis, and chemicals; supports Metric, PG, G(PF), and NPT threads; operates from -40℃ to 100℃ (up to 120℃ briefly).

Durable brass cable gland: Featuring IP68 waterproofing, acid, oil, UV, and aging resistance, and high tensile strength, it’s made of nickel-plated brass and PA66 with NBR sealing; supports Metric, PG, G(PF), and NPT threads; works from -40℃ to 100℃ (up to 120℃ briefly).

Made from corrosion-resistant stainless steel and brass with NBR or silicone sealing, it offers IP68 protection, supports Metric, PG, G(PF), and NPT threads, and operates from -40℃ to 100℃ (up to 120℃), featuring a secure clamping design for easy, reliable installation in demanding environments.

Brass cable gland (harsh environments): Constructed from nickel-plated brass and PA66 with NBR sealing, it delivers IP68/IP69K protection, resists acids, oils, UV, and aging, supports various thread types, and ensures strong, stable cable connections from -40℃ to 100℃ (up to 120℃) in harsh conditions.

Brass cable gland (general use): Made of nickel-plated brass and PA66 with NBR sealing, this IP68-rated gland supports Metric, PG, G(PF), and NPT threads, ensures firm cable locking, and allows for flexible mounting in enclosures or threaded ports, working from -40℃ to 100℃ (up to 120℃).

Cable glands play a critical role in managing cable entry points, providing reliable sealing and strain relief in electrical installations across industrial, commercial, and outdoor environments

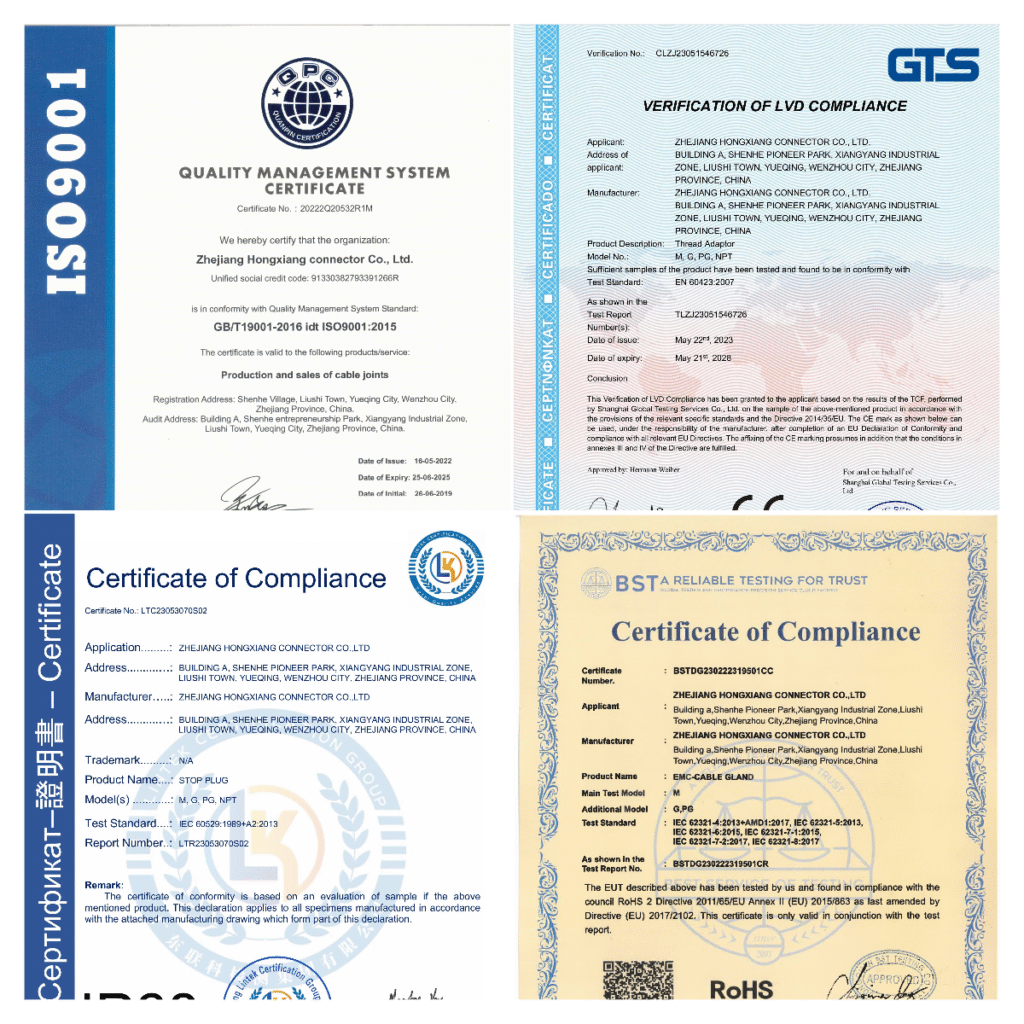

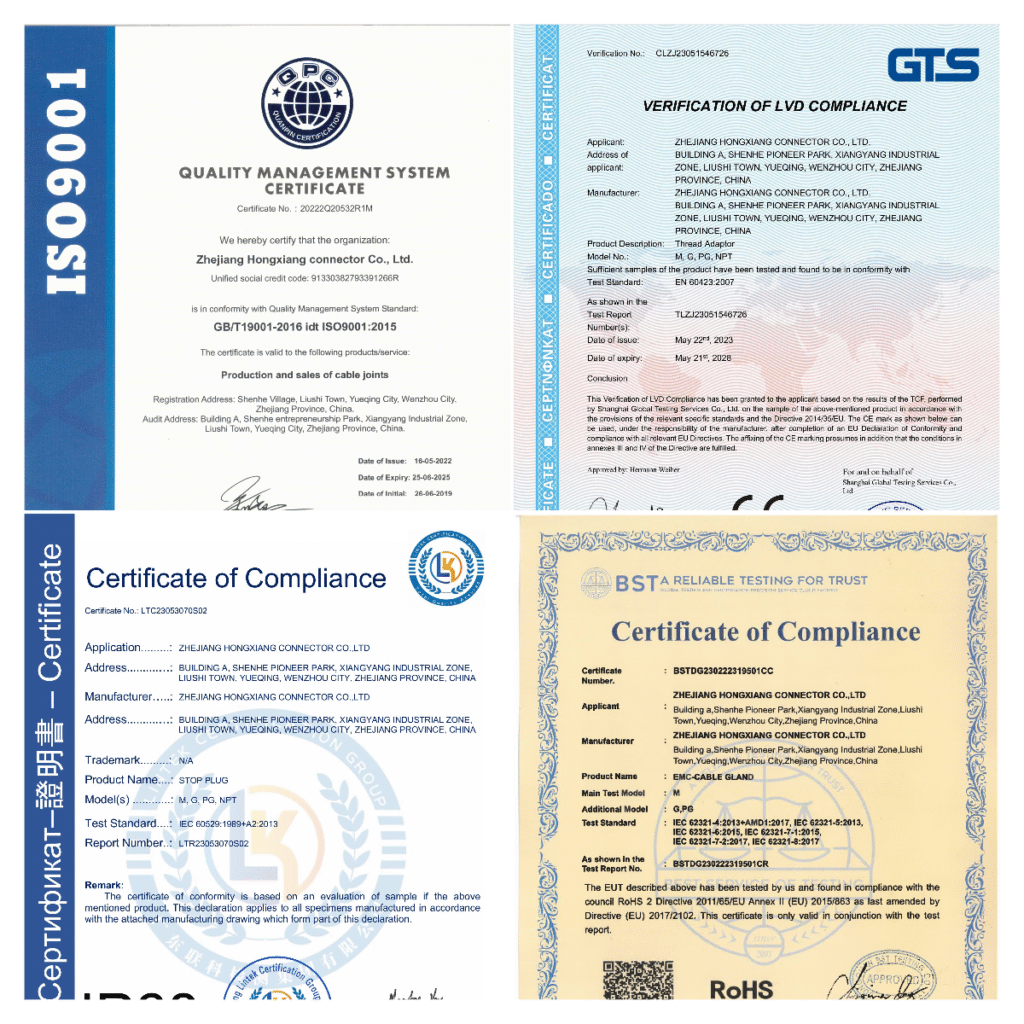

“Quality is the life of an enterprise”, The entire production process is controlled by the ISO9001 quality assurance system. We ensure that every material used in the product is strictly inspected in the selection, processing, production and commissioning stages. So that the factory’s qualification rate can reach 100%.

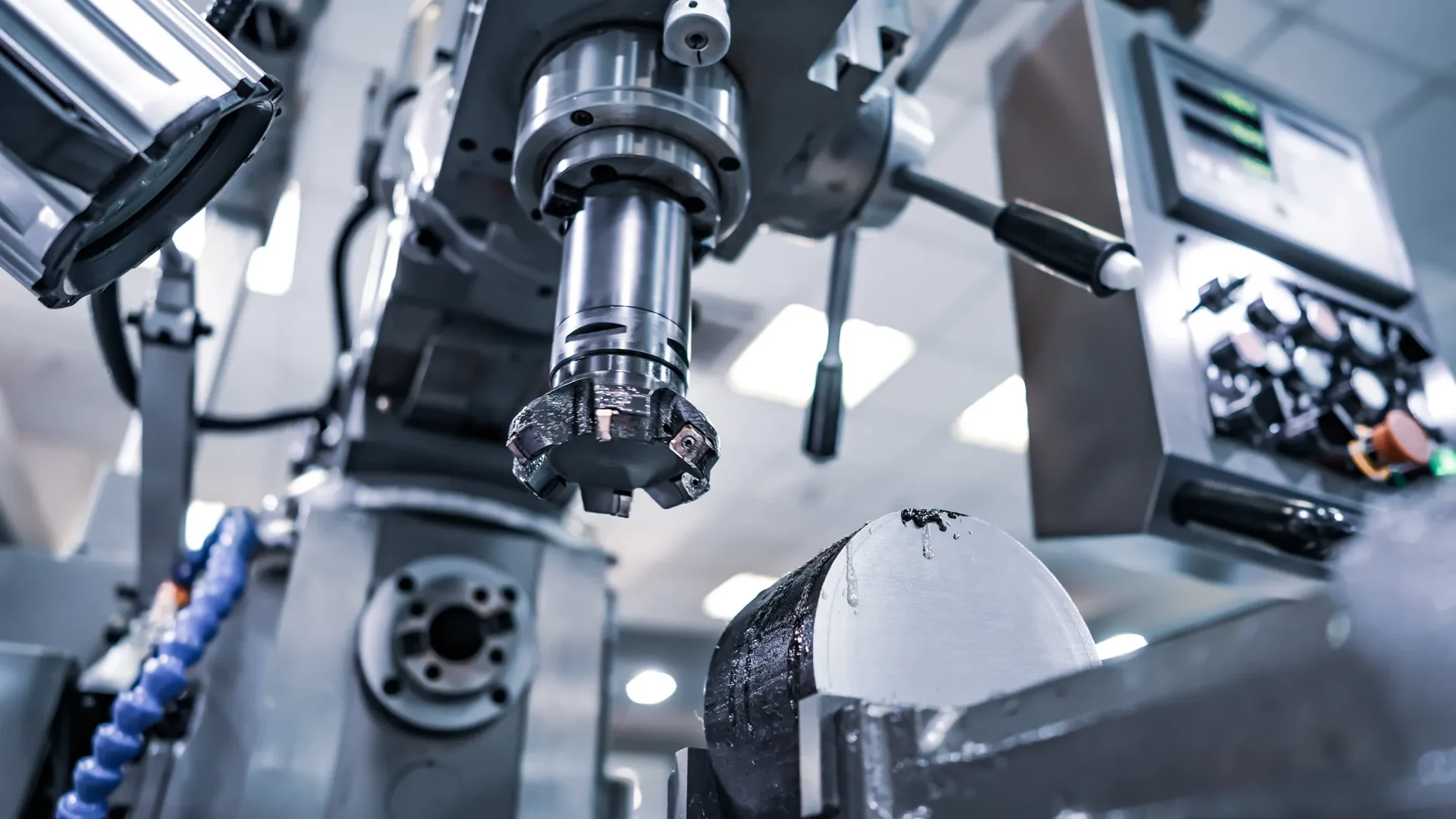

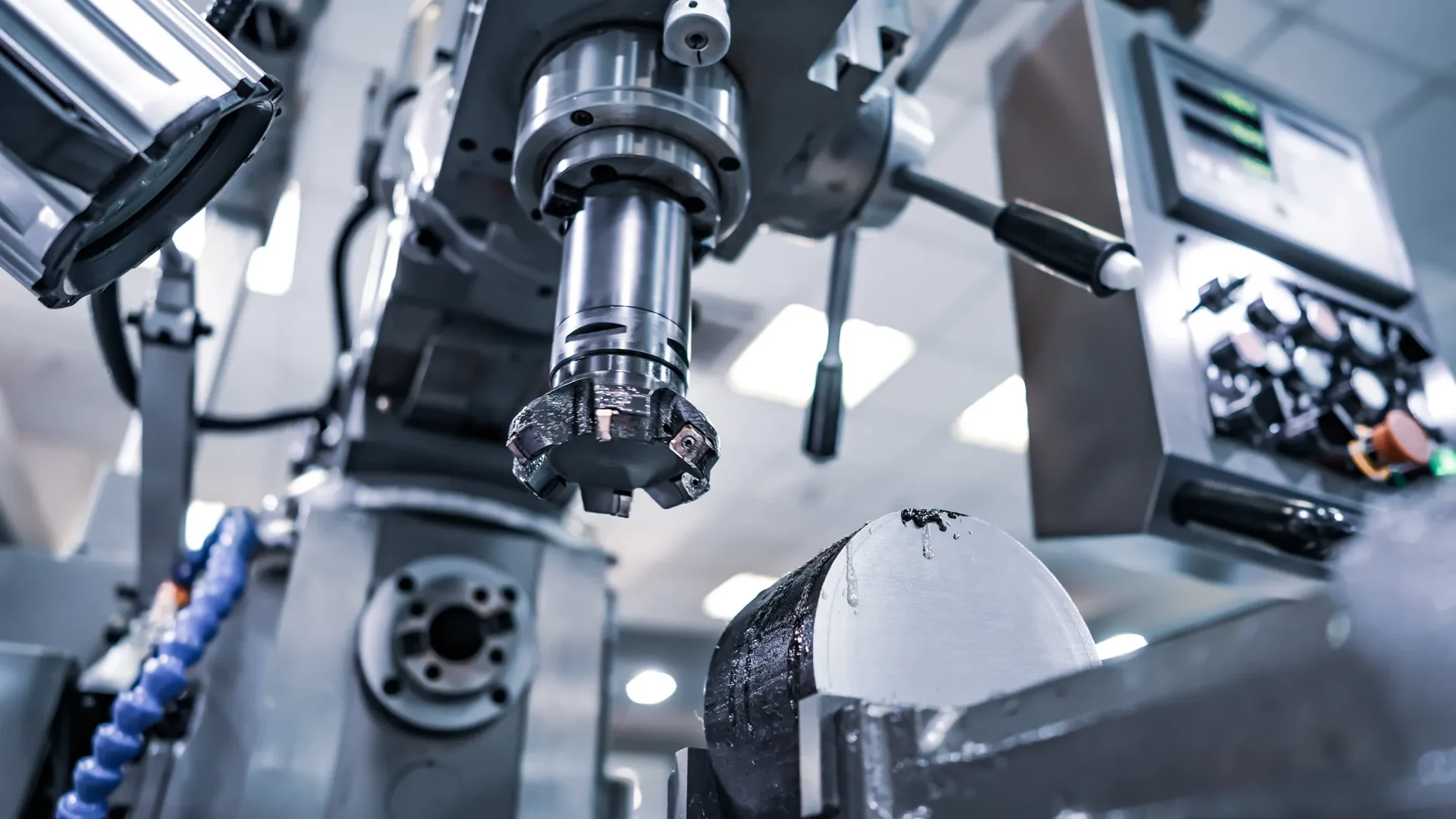

Every cable gland and accessory is carefully checked using advanced tools—including vernier calipers, thread gauges, micrometers, and hydro presses—to guarantee that all products meet strict accuracy standards and deliver reliable, high-precision performance.

Zhejiang Yuelong Electric Co., Ltd., founded in 2022 in Yueqing City, China, specializes in the development and production of cable glands and related electrical products. With core values of innovation, quality, and customer satisfaction, it holds ISO9001 and IATF 16949 certifications and exports to markets like India, Vietnam, and Poland.Similarly, a leading electrical safety device company established in 1985 spans 38,000 sqm with 1,000 employees, producing circuit breakers and contactors. Known for quality and integrity, it exports globally to countries including Malaysia, Russia, and France.Both companies prioritize innovation, quality management, and international expansion, driving their growth and strong industry reputations.

Standard workshops, spacious workshops, clean environment, and meticulous production provide quality assurance for the production process of each product. Customer-centricity, pursuit of the highest quality and lowest cost are two basic points. We are proud of our excellent quality, and our products have obtained international certifications and recognition, including ISO 9001, ROHS, IP68and CE-LVD.

We bring together highly skilled professionals and cutting-edge technology to excel in every stage of post-production, planning, and manufacturing. This integration allows us to drive continuous innovation, optimize efficiency, and maintain the highest standards of quality throughout our entire production process. By fostering a culture of excellence and leveraging the latest advancements, we ensure that our products consistently meet and exceed customer expectations.

Cable glands are used in a variety of applications to:

* Maintain the ingress protection (IP) of enclosures.

* Ensure electrical continuity and grounding.

* Prevent cable pull-out and twisting.

* Protect against environmental conditions like water, dust, and chemicals.

Consider the following factors:

* Cable diameter and type

* Application environment (indoor, outdoor, hazardous)

* Material compatibility

* IP rating required

* Thread type (e.g., PG, Metric, NPT)

Some cable glands can be reused, particularly if they’re in good condition and undamaged. However, it’s generally recommended to use new glands for critical or safety-sensitive applications.

Basic installation typically requires a wrench or spanner. Some applications may benefit from specific tools or torque guidelines provided by the manufacturer.

We will respond to your inquiry within 24 hours

We value your privacy

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.