Como instalar prensa-cabos à prova d'água passo a passo para obter proteção IP68

Saiba como instalar prensa-cabos à prova d'água com guias passo a passo para vedação IP68 usando prensa-cabos de náilon, latão ou aço inoxidável da GHX.

Leia mais

Marinha prensa-cabos à prova d'água are specially designed fittings that secure cables entering or exiting equipment on boats and ships. Their main role is to seal cables against water, dust, and other harsh elements while providing reliable strain relief to prevent cable damage from pulling or bending.

Unlike standard cable glands, marine versions offer:

| Função | Explicação |

|---|---|

| Watertight Seal | Prevents water ingress on decks, bulkheads, and engine rooms |

| Alívio de tensão | Protects cable connections from mechanical stress |

| Resistência à corrosão | Ensures durability in salty, humid marine atmospheres |

Marine waterproof cable glands are vital for:

Using the right marine cable gland guarantees your vessel’s wiring stays protected, reliable, and maintenance-free in tough offshore conditions.

When selecting marine waterproof cable glands, pay close attention to these essential features to ensure durability and safe performance in harsh marine environments.

| Material | Benefits | Ideal Use |

|---|---|---|

| Brass (nickel-plated) | Good corrosion resistance, cost-effective, durable | General marine use, lighting, solar deck seals |

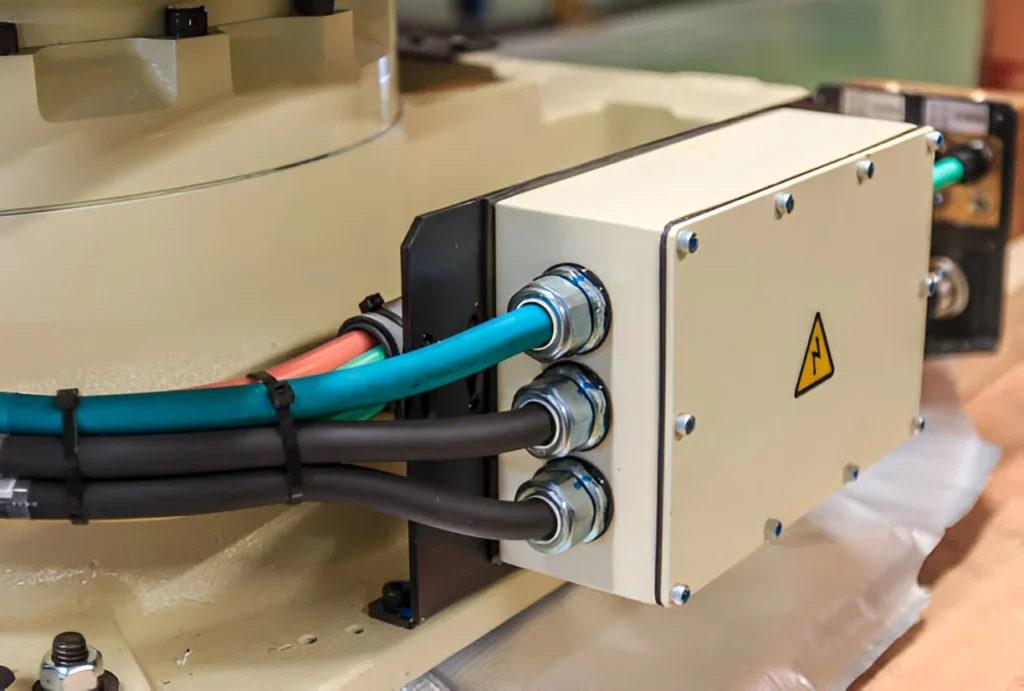

| Aço inoxidável 316 | Superior saltwater resistance, strong, long-lasting | Harsh saltwater, offshore, critical bulkheads (example here) |

| Nylon/Plastic | UV-resistant, lightweight, affordable | Non-critical areas, low exposure, internal wiring |

Choosing the right combination of these features ensures reliable cable sealing, safety, and long service life in marine environments. For example, a high-quality stainless steel cable gland with IP68 rating offers both corrosion resistance and deep immersion protection, ideal for marine professionals. Check out options like the 316 stainless steel cable gland for tough applications.

Choosing the right marine waterproof cable gland means matching the gland to your cable and environment. Here’s a quick guide to get it right:

| Recurso | Prensa-cabo de latão | Prensa-cabos de aço inoxidável | Prensa-cabos de nylon |

|---|---|---|---|

| Resistência à corrosão | Good (nickel-plated for marine use) | Excellent (316 marine-grade steel) | Moderate (UV-resistant versions available) |

| Durability | High but can tarnish | Very high, resists saltwater damage | Moderado |

| Custo | Moderado | Custo mais alto | Low cost |

| Peso | Mais pesado | Heaviest | Leve |

| Ideal Use | General marine deck pass-throughs | Harsh saltwater, engine rooms | Less harsh areas, interior or protected zones |

| Classificações de IP | Up to IP68 | Up to IP68 | Up to IP67 |

Picking the right cable gland means balancing cost, durability, and protection according to where and how you use it. For more on thread types and stainless steel options, explore our guide on choosing the right size and specification of stainless steel cable glands.

With this approach, you’ll secure your cables properly and keep your marine systems safe from water and corrosion.

When it comes to marine waterproof cable glands, several leading options stand out for their reliability and durability in tough marine environments. The best choices offer a mix of high IP ratings, corrosion resistance, and easy installation to ensure cables stay protected against water ingress and mechanical strain.

GHX Marine Waterproof Cable Glands are a top pick for professionals and boat owners alike. They come in brass, stainless steel (316 marine grade), and UV-resistant nylon variants, covering a wide range of needs from heavy-duty engine rooms to lightweight deck pass-throughs. Their glands feature a high IP68 sealing level, meaning they provide excellent protection even under continuous water immersion.

One key advantage of GHX cable glands is precise sizing options that accommodate various cable diameters, including armored and unarmored types. This ensures a perfect fit that secures cables and prevents leaks. Plus, their superior corrosion resistance helps them withstand harsh saltwater conditions, extending the lifespan of your installations.

For those needing brass options with excellent conductivity and durable seals, GHX offers premium choices like their high-strength sealed corrosion-resistant brass cable gland, ideal for demanding marine environments. Their stainless steel range is perfect for critical applications requiring maximum saltwater durability, while nylon cable glands provide a cost-effective solution without compromising on UV resistance.

Overall, GHX marine waterproof cable glands bring together reliability, performance, and ease of use—making them a solid choice for anyone outfitting boats, offshore rigs, or sea vessels with secure, waterproof cable entries.

Getting your marine waterproof cable glands installed correctly is key to keeping cables secure and watertight. Here’s a simple step-by-step guide for a solid setup.

Installing top-quality marine cable glands right the first time keeps your wiring safe and your vessel protected against harsh marine environments.

To keep your marine waterproof cable glands working reliably, regular inspections are crucial—especially in salty, harsh marine environments. Check your cable glands for any signs of corrosion, seal wear, or cracking. Corrosion, particularly on brass or stainless steel cable glands, can compromise the watertight seal and lead to leaks. Seal degradation, like hardened or cracked rubber gaskets, signals it’s time for a replacement to maintain full protection.

Here are easy maintenance tips to extend the lifespan of your marine cable glands:

For longevity in tough marine conditions, consider these extra steps:

Regular care ensures your marine cable glands keep your wiring safe and dry, saving you from costly repairs and downtime.